Place of Origin:China

Product name:

Two-component Adhesive Epoxy Glue Automatic Mixing Dispensing Robot

Mixed ratio:

100:100~100:20 or 100:20~100:10

Operational viscosity:

<20000CPS

Spit glue speed:

1g/sec~15g/sec 5g/sec~30g/sec

Dispensing stroke x/y/z (mm):

600/300/100mm(customized)

XYZ axis stepper motor:

High-precision micro-stepping motor with driver

Metering motor:

Stepping motor

Match Mixer:

Static Mixer & Dynamic Mixer

Storage Tank:

15L/30L/70L (customized)

Condition:

New

Video outgoing-inspection:

Provided

Machinery Test Report:

Not Available

Marketing Type:

Hot Product 2019

Warranty of core components:

1 Year

Core Components:

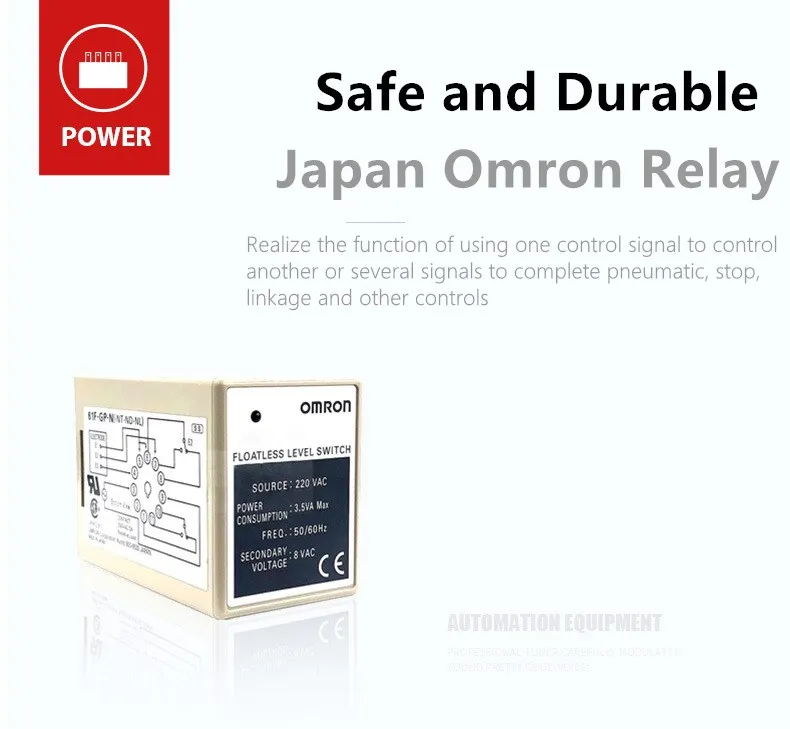

PLC, Engine, Motor, Pump

Warranty:

1 Year

After-sales Service Provided:

Video technical support, Online support

After Warranty Service:

Video technical support, Online support

Local Service Location:

India

Showroom Location:

India

Applicable Industries:

Printing Shops, Construction works , Digital Electronics, LED Lighting, Wirelss Communication, Jewelry Industry

Supply Ability

Supply Ability

5000 Set/Sets per Month

Lead Time:

Quantity(Sets) 1 - 1 >1

Est. Time(days) 20 To be negotiated

Two-component Adhesive Epoxy Glue Automatic Mixing Dispensing Robot Dispenser for Meter Mix Dispense

Basic Information

Model | |

Dispensing stroke x/y/z (mm) | 600/300/100mm(customized) |

Proportioning accuracy | ±2% |

Spit out accuracy | ±2% |

Mixed ratio | 100:100~100:20 or 100:20~100:10 |

Spit glue speed | 1g/sec~15g/sec 5g/sec~30g/sec |

Maximum Moving speed | 300mm/sec |

Operational viscosity | <20000CPS |

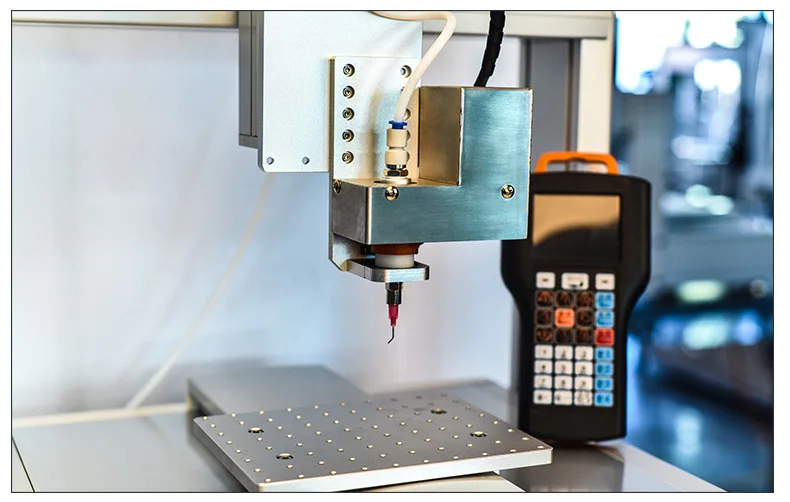

Measurement method | Stepper motor + gear pump/rotary plunger pump servo motor + piston pump |

Transfer method | Micro stepping motor + timing belt |

Power supply | AC220V 50HZ 2.5KW |

XYZ axis stepper motor | High-precision micro-stepping motor with driver |

Tank mixing system | One set/two sets (optional) |

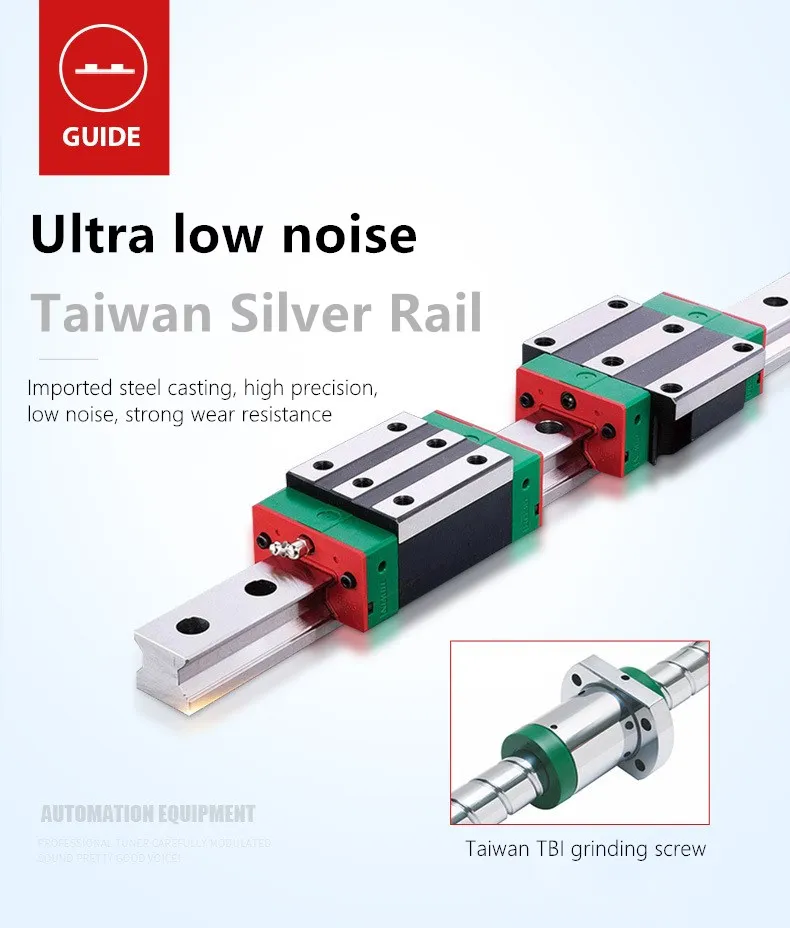

Guide | Taiwan TBI |

Static mixing valve | Optional dynamic mixing valve according to glue |

High-precision metering pump | Gear pump or rotary plunger pump/piston pump can be selected according to the glue |

Metering motor | Stepping motor |

Storage Tank | 15L/30L/70L, optional vacuum deaeration or heating function |

Product Usage:

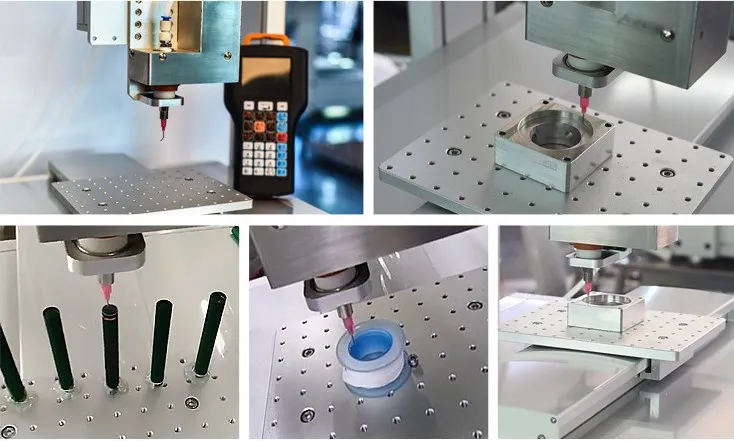

AB double-liquid glue filling machine is an automatic machine that specializes in controlling fluids, dripping, coating, and potting the liquid on the surface or inside of the product to achieve the functions of sealing, fixing, and waterproofing. It is generally used Mostly two-component glue. Mainly used for bonding, pouring and coating of glue, oil and other liquids in the product process

Features:

1. Chinese/English operation interface, simple and easy to learn, professional error correction and foolproof design

2. Powerful lesson editing operating system, which can store multiple sets of data, and improve the programming time for line change

3. The three-axis platform can be customized to realize contact and quick glue filling, without jitter, and improve stability

4. The glue output ratio, time, speed, amount of glue, easy to set

5. Adjustable instantaneous suction shut-off valve, good ratio, anti-drawing, glue dripping, and a new breakthrough in glue overflow

6. Precise wear-resistant metering gear pump, strong continuous glue output, can be customized

7. Automatically develop the speed servo dynamic mixing system to ensure uniform mixing and unique rotating seal design

8. Equipped with automatic pressure sensor, timing discharge function and automatic cleaning function

9. Multi-layer filter system for material barrel, and equipped with sensitivity liquid level sensor alarm system

Note: The AB plastic bucket can be equipped with automatic mixing, automatic heating, and vacuuming functions

Basic Technical Parameters